|

NEW: For өicro200 Langmuir trough see Modifications page.

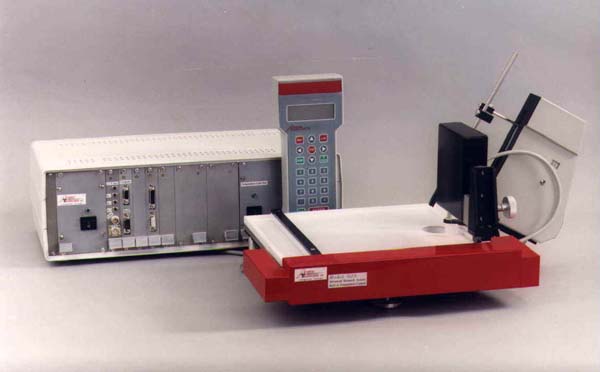

Model 503/BT/TM/HT/LD system with built-in temperature control, tilt

mechanism for the dipping module, hand-held panel and large dipping well. Features

Model 503/BT/2B/DM with built-in temperature control, 2 barriers and detachable mechanism for one of the barriers is integrated on the microscope table of an epifluorescent microscope. Specifications of the 500 series LB film equipmentAll systems require IBM PC compatible computer with 386 processor or higher not shipped with the system. Trough and barrierManufactured from bulk PTFE (Teflon). Dipping well is sealed with waterproof adhesive or is integrated. 1.2 mm trough bottom cemented to aluminium plate for thermal control. Usable area: 271 x 218 mm = 590 cm2 Minimum area: 40 x 218 mm = 87 cm2 Compression ratio: 590 / 87 = 6.8 Depth: 4 mm. Optionally the barrier can be manufactured from hydrophilic Delrine. Dipping well: situated at one side of the trough, depth 54 mm, diameter 44 mm. Optionally: integrated dipping well with depth of 13 mm. Overall volume: 0.4 l with large dipping well. Other sizes include miniatures trough and/or built-in dipping well. We can manufacture to customers specifications. Film balance systemMethod of measurement: Wilhelmy plate method with 16 mm wide filter paper. Very robust unbreakable design. Maximum filter paper displacement: 0.1 mm. Precise manual mechanism for vertical positioning and calibration against water with 50 mm range. Measuring range: Precisely tuned for 0 - 75 mN/m Measuring rate: maximum 10 points per second (internally 20 pps) Resolution: 0.0025 mN/m (internally 4 times greater). Unique 22 bit Analogue-to-Digital converter is built-in with much higher internal resolution and accuracy. Possibility for averaging between 0 and 128 subsequent data points. Nonlinearity: better than 0.1 % of full scale Reproducibility: Вұ 0.05 mN/m. Short term noise: Вұ 0.02 mN/m. With additional averaging: Вұ 0.005 mN/m. Long term drift at constant ambient temperature: Вұ 0.05 mN/m for 6 hours. Accuracy of constant surface pressure control: Вұ 0.03 mN/m at equilibrium. Built-in software temperature compensation for water tension change with temperature. The absolute accuracy of measurement is limited by external factors (wetting angle, calibration accuracy, etc) to 0.1 mN/m. However changes in isotherms of less than 0.02 mN/m can be reliably measured especially with the off-line averaging. Built-in temperature control (optional)A unique built-in temperature control (patent pending) allows unsupervised measurement of Isobars and Isochores, or multiple thermal cycles for film quality improvement. Completely integrated electronics with independent power switch. Requires only a minimum stream of tap water supplied via tubing inlets. Hardware and software protection for overheating. Range: 5 - 40 OC at 20OC ambient. Software limited. Accuracy: Вұ 0.05 OC after one hour of stabilisation in 12 to 28OC region. Max. Вұ 0.2 OC outside this region. Maximum rate of temperature change: 1.5OC/min limited by the time for water to equilibrate in the dipping well where a thermometer is situated. Two digital thermometers with 0.5OC absolute accuracy and 0.01OC resolution are included. No recalibration is ever needed. One thermometer is sealed at trough bottom. The other is in quartz ampoule for cleaning, situated in the dipping well. Film area controlDC servomotor with built-in tachometer (Maxon, Switzerland) and linear analogue feed-back loop for vibration free, low unevenness, long life, wide dynamic range motion. The mechanism moves on a precision slide rail (Nippon Bearing, Japan). Barrier speeds min/max: 0.001 to 8 mm/s (0.06 to 480 mm/min) defined in 8200 steps by 14 bit Digital-to-Analogue Converter. Position sensor: Digital encoder (Bourns, USA) with 0.005 mm absolute accuracy. Autozero feature on power on. Up to 15 cycles of compression and decompression within predefined barrier positions or predefined surface pressures. Three modes of compression: constant velocity, or equilibrium pressure compression with parameters for velocity, pressure step and minimum slope Dp/Dt after which compression is reactivated, or constant strain compression. Film deposition systemSame precision mechanism as in film area control. Stroke: 120 mm. Lift speeds min/max: 0.001 to 8 mm/s (0.06 to 480 mm/min) defined in 8200 steps by 14 bit Digital-to-Analogue Converter. Individually adjusted velocity for the first layer and for the up and down movements. Position sensor: Digital encoder (Bourns, USA) with 0.005 mm absolute accuracy. Autozero feature on power on. Deposited layers: up to 32000 Individual dwell times in the upper and lower position of up to 32000 s. Tiltable lift mechanism (option): 0 - 90 deg. with readout and possibility to reposition for dipping well targeting. The software takes into account the lift tilt for correct Transfer ratio calculations. Hand held panel (optional)An unique device which communicates with the controller via RS435 protocol. It has a 14 mm large 8 digit alphanumeric display LED display for large distance viewing of most important experiment parameters; 4 row x 20 characters backlit LC display, custom designed water-proof front keypad. The panel can be positioned in another room to avoid entering the clean area. Power supply230, 127 or 100 V, EM emission free. 400 W with the built-in temperature option; 50 W otherwise. |